Customer Success Stories

Loginets has helped numerous companies to streamline their operations with our unique software solutions.

We have customers in the construction, heavy industry and property and equipment maintenance sectors.

Check out some of our success stories below.

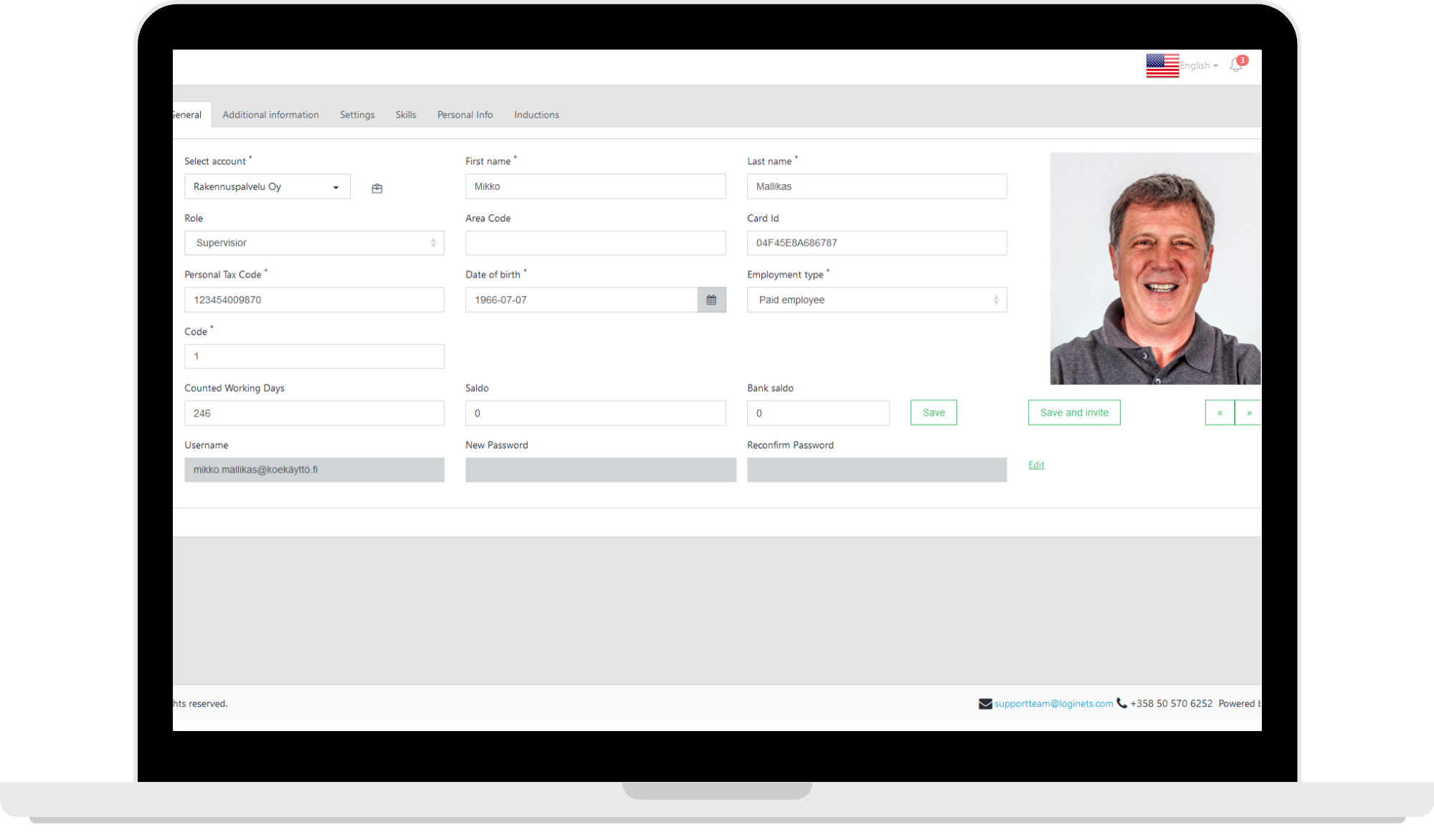

Sample users of our software solutions

Customer statements

“Using the software has been easy and the customer service is excellent. The deployment is simple because the software and the reader are delivered ready for use. The system’s benefits are varied – access control provides information for cost control and invoice monitoring as you know the contractors work hours. If there are any technical problems the support works well. In addition, the price of the system is competitive. I can recommend it.

“After evaluating the readers and software in the markets we chose the Nopsa system because the reader device which is LogiNets Oy’s own production was the most credible for construction. Also the system was applicable according to our needs. The device deliveries and system implementation went very well. The reader’s deployment is extremely simple – just plug and play.”

“I like the Nopsas’ mobile inductions. Inductions are easy to mark as completed, once employee data has been collected through the VALTTI smart cards.”

“I like the Nopsa software. The updated user interface is visual.”

“Everything works extremely well. I have been satisfied with the software and especially with the prompt and friendly customer support. The smart card reader and software are fast and easy to use. I’ve come in contact with larger organizations who are still keeping track of construction site attendance and site inductions with pen-and-paper methods. LogiNets has made this process fast and agile.”

“Nopsa has served our needs well. The reports generated by the system are very clear. I have recommended Nopsa to other organizations as well”

“The system facilitates daily operation – access control and reporting to the tax administration are handled electronically. The biggest advantage of an electronic access control system is in the fact that I can focus on the project work and my time is not spent on collecting and reporting information.”

“With the Nopsa software work hours go directly to payroll. The system eases time tracking. I do recommend it!”

It’s an insanely good system. The benefits gained from using the system are huge, running a large project without such a system would have been difficult. The material tracking system is easy to use. Using the system reduces the risk of errors compared to doing the same things with excel templates.

With very good & clear video instructions the system was easy to use.

Even though it is the first time I have used your system, it was easy to handle and to create the packages, containers and shipments. I have only been in contact with your support one time and did then receive an answer the same day, that solved my problem. Excellent!

Customer cases

UPM has made an investment decision to construct a 2,1 million tonne greenfield eucalyptus pulp mill near Paso de los Toros. The total investment of the project exceeds USD 3 billion. The operation of the new pulp mill generates 10,000 permanent jobs and involves in the production chain more than 600 small and medium size local companies. More information on the investment can be found via UPM Paso De Los Toros website.

UPM uses the Material Tracking System (MHS) to track equipment in the project. UPM’s target for using the Material Tracking System was to introduce material and technology delivery suppliers directly to the contractors through a common system and database where the deliveries and their contents could be easily traced.

Koiviston Vihertyö Oy is a company concentrated on environmental building in the Helsinki metropolitan area and in Mikkeli.

The challenge for the company was manual time sheet reporting and salary payment which took a lot of time. Work hour reports were late and management had to run after time sheets.

The solution was to implement the use of Nopsa software in 2005. Work hours are now reported electronically via a mobile phone. Independence from devices that are built in on a site is highly important for companies where the employees go to different locations during the day.

The benefits include more precise and faster time sheet reporting. The implementation and use of the software is simple. Also the employees have been very pleased with it.

Tapiolan Lämpö Oy provides property maintenance and management services. It is responsible for more than 500 properties’ maintenance.

The challenge for the company was getting real-time information on the work done in the field and monitoring the profitability of different properties.

The solution was to implement the use of the NOPSA service in 2008. Now work can be signed off with just one touch of the mobile when exiting a property. In 2012 the use of the service was expanded to cover also plowing and sandblasting work. In 2014 the company started using the extended version of VALPAS service.

The benefits include reliable and real-time maintenance work sign offs, specific property based cost control and more efficient use of human resources including comprehensive information sharing and communication in property management. Also, the employees have been content with getting an easy access to property task lists with their own mobile phones.

Sumitomo SHI FW supplies power plant and industrial boilers all over the world. The company has more than 600 suppliers worldwide.

The challenge for the company was the timely coordination of goods delivery from hundreds of different suppliers to sites all over the world. The delivery communication was done by fax, phone or e-mail. The stock inventory at different sites was handled manually.

The solution was for Sumitomo SHI FW to implement the use of the Material Handling System in 2004. The cloud-based software is a communication platform for the supplier and the customer. The software covers communication exchange from the order’s reception until the delivery and installation at the site.

The benefits are real-time management of the delivery of the goods, quality delivery documents that meet customer standards and ability for both parties to see and be part of the communication and delivery process.

Some of our customers

Sample users of our MHS- software