Track materials in industrial projects

-

- Visibility for the whole logistics chain from procurement to installation

- Collaboration tool for the whole project network

- Complete your project on time and on budget

Track materials in industrial projects

Items ordered

Packages delivered

Containers delivered

Shipments completed

Are you using Excels to manage material deliveries?

Delivery info often remains trapped in excels and emails, wasting time on manual updates and complicating sharing with relevant parties.

Is time wasted looking for lost materials?

If a material’s location is unknown, time is wasted searching, halting project progress and sometimes requiring costly air freights for redelivery.

How will you ensure your project is on time and on budget?

77% of capital projects face delays exceeding 2 years, incurring hefty costs. Efficient materials management is vital for timely project completion.

Transform how you manage material deliveries in your industrial project

The Material Handling System (MHS) has been developed to resolve the key issues in tracking materials in capital-heavy construction projects and to ensure timely commissioning of the plant.

- Common materials data-base for all project parties

- Transparent material flows from procurements to site installation

- Track individual items with the master search tool

- Get rid of manually filling in Excel files and sending emails

MHS is a modern material tracking software designed specifically for large industrial projects. It is suitable for projects in various industries such as oil & gas, power, pulp & paper, mining, and iron & steel. The software gives stakeholders across the supply chain access and visibility into the project. The tool can be used by project managers, project engineers, procurement, material suppliers, forwarders, contractors, logistics managers and project warehouse managers.

The Material Handling System has been in use in international capital projects since 2003. The features of the software have been developed with the latest technologies based on collaboration with leading Finnish heavy industry companies.

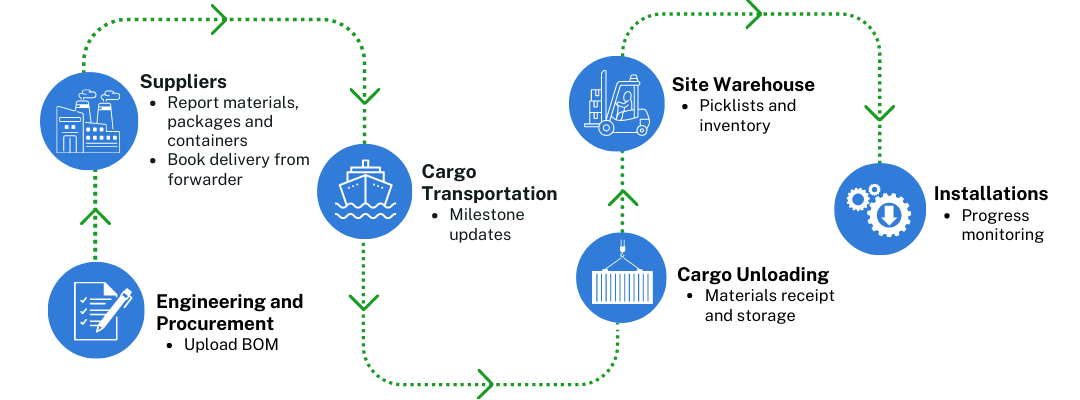

Material tracking throughout the entire logistics chain

Discover the MHS Modules

The material tracking system supports processes from procurement to site installation.

For a free analysis of your business needs you can schedule a consultation with one of our logistics experts.

Engineering and procurement

Shipment management

Share delivery milestones with the entire project network

Warehouse software

Tools for construction site warehouse management

Transparent material tracking

Form packages, containers and delivery documentation

Material inspection

Unload and inspect goods at site using a mobile application

Frequently asked questions

Which languages are supported? How long is the set up process? Etc.

For a free analysis of your business needs you can schedule a consultation with one of our logistics experts.

Benefits of using the material tracking software

- Manage materials efficiently and complete your project on time and on budget

- Shared database and collaboration tool for the entire project network

- Locate any component with a single search in the system

- Automatically generated packing lists and labels

- Manage materials based on set milestone dates

- Unload and inspect goods at site with a mobile app

- Ensure timely delivery of goods and avoid missing deadlines due to missing materials

- Transparency of information with shipments, containers, packages and items

- Electronic shipment bookings

- Accurate info on laydown area placements at site

- Pick-lists and automatic inventory updates

- No more time spent on Excels, emails and phone calls

Customer stories

Read more here!

UPM used the Material Tracking System (MHS) to track equipment in the project. UPM’s target for using the Material Tracking System was to introduce material and technology delivery suppliers directly to the contractors through a common system and database where the deliveries and their contents could be easily traced.

The challenge for the company was the timely coordination of goods delivery from hundreds of different suppliers to sites all over the world. The delivery communication was done by fax, phone or e-mail. The stock inventory at different sites was handled manually.

The solution was for Sumitomo SHI FW to implement the use of the Material Handling System in 2004. The cloud-based software is a communication platform for the supplier and the customer. The software covers communication exchange from the order’s reception until the delivery and installation at the site.

The benefits are real-time management of the delivery of the goods, quality delivery documents that meet customer standards and ability for both parties to see and be part of the communication and delivery process.

MHS users over the years

A word from our CEO

A huge amount of work has been done to solve the major issues with material deliveries to construction sites. The Material Handling System is a result of over 20 years of work, including on-site interviews with hundreds of project management professionals, brainstorming sessions, piloting of new work practices and incorporating wireless technologies in every-day work at construction sites. We want to thank our partners in leading Finnish heavy industry companies for their cooperation in developing the system over the years including ABB Oyj, Andritz Oy, Metso Paper Oyj, Sandvik Mining and Construction Oy, Wärtsilä Oy, Sumitomo SHI FW and many others. The system has been in use in capital projects since 2003.

Why choose MHS?

20 Years of Experience

Customized Solution

Our service is always offered as a customized solution for your organisation’s needs. It is scalable for any size industrial projects, up to projects which receive thousands of containers. It is also compatible with all material types (piping, bulks, steel structure, tagged equipment etc.)

Seamless Integration

The material tracking system has existing integrations with process planning systems, procurement softwares and forwarding systems. Our software is built using modern API’s, which allows for building seamless integrations.

Continuous Development

MHS is constantly evolving based on the needs and feedback of our customers. We develop the service together with our customers daily to remain a pioneer in the field.

Deployment in 5 days

You can have the software in use as fast as in 5 days and all our customers receive a dedicated server. We help make the entire onboarding process easy from implementation to training and support with data transfer from any old systems.

Fast Customer Support

Material Tracking Software packages

- Agile tool for tracking materials in a small project (investment value less than 50 million €)

- BoM management

- Tools for reporting packages, containers and deliveries for the material suppliers

- Shipping documents

- Materials master search

- Technical support for 10 key project personnel

- PDF and video user guides

- Mobile app for unloading goods at site

- For a medium-sized project (less than 500 million €), with the Basic features, and:

- Technical support for the project network via email

- Tools for site warehouse management (inventory and pick-lists)

- Contractor views and dashboards

- Automatic email notifications of incoming deliveries

- Shipment bookings to freight forwarder via automatic emails

- Mobile app for unloading goods at site using QR-codes on shipping documents. Tools for tracking goods at project site on the go with a mobile app

- For a mega-scale project (investment value over 500 million €).

- A comprehensive materials tracking system tailored to your projects needs! Build innovative solutions for materials tracking with our project logistics expert and product development team. For example:

- Integration with procurement and freight forwarder systems

- Erection status monitoring

- Weekly data integrity checks

- Build automatic notifications for product deficits

- Onboarding sessions hosted via online meetings bi-weekly for the first 4 months of the project

- And much more

Are you looking for material tracking software for your next project?

Your organization will be assigned to a project consultant, who will work with you to identify which modules of the material tracking software would best fit your project’s material logistics.

You will work with the same project consultant from your first contact until your capital project construction is complete. Now we can begin tracking materials in your project efficiently!