Material logistics trends 2024

As technological advancements accelerate and the dynamics of international trade evolve, the landscape of industrial projects globally is undergoing rapid transformation. Within this shifting context, the concept of material logistics becomes crucial, playing a central role in driving efficiency, cutting costs, and ensuring the seamless flow of operations.

The importance of material logistics in large industrial projects cannot be overstated. It serves as the backbone of project management, directly impacting the overall project timeline, budget, and quality. Effective material logistics management ensures that projects are completed on schedule, within budget, and to the required quality standards. This safeguards profitability and enhancing customer satisfaction. Furthermore, in an era where projects are becoming increasingly complex and geographically dispersed, the role of material logistics as a critical success factor is amplified, necessitating innovative solutions and technologies to meet the demands of modern industrial projects.

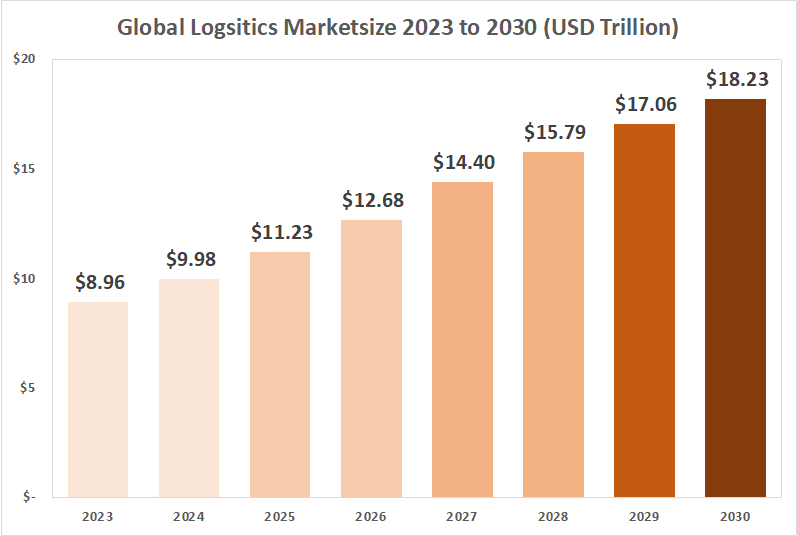

The global logistics market size, which accounted for USD 8.96 trillion in 2023, is a testament to the sector’s vast scale and its critical role in the world economy. It is expected to grow to be worth around USD 18.23 trillion by 2030, with a noteworthy CAGR of 10.7% from 2023 to 2030. This expansion reflects not only the growing complexity and geographical dispersion of industrial projects but also the increasing need for innovative solutions and technologies to navigate these complexities efficiently. Exploring the material logistics trends of 2024, we see how technological advancements, sustainability practices, and the drive for efficiency are shaping the future of industrial project management.

Technological Advancements in Material Tracking and Management

The material logistics industry is undergoing its most significant transformation yet, driven by rapid technological advancements that are setting new benchmarks for efficiency, transparency, and reliability in large industrial projects.

Two of the most impactful developments in this arena are the integration of the Internet of Things (IoT) and the utilization of Artificial Intelligence (AI) and Machine Learning (ML), each playing a crucial role in revolutionizing material tracking and management.

Integration of IoT (Internet of Things) in Material Logistics

1. Smart Sensors for Real-time Tracking: The deployment of IoT in material logistics, particularly through smart sensors, has allowed for real-time tracking capabilities that were previously unimaginable. These sensors, attached to materials or equipment, transmit data continuously about their location, condition, and environment. This constant flow of information enables project managers to monitor materials in transit or on-site in real time, significantly reducing the risk of loss, damage, or delays.

2.Technological Solutions for Real-time Tracking: Beyond tracking, IoT technologies like 5G can improve visibility across the entire supply chain. By integrating data from various sources, including suppliers, transporters, and on-site inventory, stakeholders gain a comprehensive view of the material lifecycle. This enhanced visibility supports better decision-making, allowing for adjustments in procurement, storage, and deployment strategies based on real-time information, thus enhancing overall project efficiency and cost-effectiveness.

Utilization of AI (Artificial Intelligence) and Machine Learning

1. Predictive Analysis for Demand Forecasting: AI and ML technologies are at the forefront of predictive analytics, offering profound insights into demand forecasting. By analyzing vast amounts of historical and current data, these technologies can identify patterns and predict future material needs with remarkable accuracy. This capability enables companies to optimize their inventory levels, reducing both shortages and excesses and ensuring that materials are available when and where they are needed.

2. Optimization of Supply Chain Routes: AI and ML also play a pivotal role in optimizing supply chain routes. By considering various factors such as traffic patterns, weather conditions, and delivery schedules, these technologies can determine the most efficient routes for material transportation. This optimization not only reduces delivery times but also lowers transportation costs and minimizes the environmental impact of logistics operations. Furthermore, AI-driven route optimization can enhance the resilience of the supply chain, enabling quick adjustments to unforeseen disruptions and maintaining the flow of materials to keep projects on track.

Sustainable Material Logistics Practices

As the global focus on sustainability intensifies, large industrial projects are increasingly adopting practices that minimize environmental impact without compromising efficiency. Sustainable material logistics practices are at the heart of this shift, incorporating eco-friendly packaging solutions and green transportation methods to reduce the carbon footprint of logistics operations.

Eco-friendly Packaging Solutions

The move towards eco-friendly packaging solutions represents a significant step forward in reducing waste and promoting sustainability in material logistics. Innovations in this area include the use of biodegradable, recyclable, or reusable materials that offer the same level of protection for goods as traditional packaging but with a fraction of the environmental impact. The adoption of eco-friendly packaging is a clear indication of a company’s commitment to sustainability, enhancing its reputation among consumers and stakeholders who are increasingly environmentally conscious.

Green Transportation Methods

The transportation of materials stands as a major source of carbon emissions within the supply chain, with the transportation sector, including shipping, accounting for approximately 20.2% of the world’s total CO₂ emissions. This substantial figure positions it as the second-largest contributor to global carbon pollution. In response to this environmental challenge, large industrial projects are increasingly adopting greener transportation methods.

1. Electric and Hybrid Vehicles: The integration of electric and hybrid vehicles into logistics fleets is a key strategy in reducing emissions. These vehicles emit far fewer pollutants than their conventional counterparts. As battery technology advances and charging infrastructure expands, electric and hybrid vehicles are becoming a more viable and cost-effective option for logistics operations of any size, region, or industry.

2. Emphasis on Rail and Water Transportation: The focus on rail and water transportation offers substantial environmental benefits over road transport by significantly reducing emissions per ton-mile. Notably, shifting freight to rail can remove hundreds of trucks from highways and lower greenhouse gas (GHG) emissions by up to 75%, on average. Similarly, water transportation through inland waterways and oceans presents a sustainable alternative for moving large volumes of materials across great distances. By adopting new technologies such as biofuels and modern cargo sails, logistics organizations can reduce their carbon footprint while protecting their bottom line.

Robotics and Automation in Material Handling

Robotics, and automation have emerged as game-changers in material handling. These technologies not only streamline operations but also significantly reduce the likelihood of errors and the need for manual labor. Within this context, automated warehousing systems have become pivotal in transforming material logistics from a series of manual tasks into a seamless, automated flow.

Automated Warehousing Systems

Automated warehousing systems represent the integration of advanced technologies and robotics in the storage and management of materials. These systems are designed to optimize space utilization, enhance inventory control, and expedite material retrieval and storage processes. The implementation of such systems has led to unprecedented levels of efficiency and accuracy in warehousing operations

Autonomous Robots for Material Movement: These robots are equipped with sensors and navigation technologies that allow them to transport materials within the warehouse safely and efficiently. From moving products between storage locations to delivering them to picking stations, these autonomous robots minimize the need for human intervention, thereby reducing labor costs and improving safety. Moreover, their ability to operate around the clock enhances operational throughput, making them invaluable assets in material logistics.

Automated Picking and Packing Processes: In addition to autonomous robots, automated warehousing systems have revolutionized picking and packing processes. Companies like Amazon use robotic arms, automated conveyors, and sophisticated software to accurately pick items from storage locations and prepare them for shipment with minimal human involvement. This automation not only speeds up the picking and packing process but also significantly reduces the chances of errors that can occur with manual handling. Furthermore, the system’s ability to track inventory in real-time ensures that stock levels are accurately maintained and orders are fulfilled promptly, contributing to higher levels of customer satisfaction.

Collaboration and Connectivity in Supply Chain Networks

In today’s complex and dynamic market, the success of large industrial projects increasingly depends on seamless collaboration and connectivity within the supply chain network. The integration of digital platforms has revolutionized how companies communicate and collaborate, breaking down traditional barriers and fostering a more cohesive and transparent supply chain ecosystem.

Enhanced Communication through Digital Platforms

By adeptly managing procurement, storage, and timely use of materials, project managers can mitigate the risks associated with material shortages or supply chain disruptions, safeguarding both the project timeline and budget.

1. Cloud-based Collaboration Tools

The advent of cloud-based collaboration tools has been a major catalyst for improving communication within supply chain networks. Tools, such as the Material Handling System, provide a unified platform where all stakeholders, including suppliers, manufacturers, logistics providers, and customers, can interact and share information in real-time. The cloud infrastructure ensures that these tools are accessible from anywhere, at any time, facilitating decision-making processes and enabling a more agile response to market changes.

2. Real-time data Sharing Across Stakeholders

Real-time data sharing is another critical aspect of digital platform-enabled collaboration. By leveraging IoT devices, RFID tags, and other technologies, stakeholders can obtain live updates on material movements, inventory levels, and delivery statuses. This instantaneous sharing of data ensures that all parties have access to the same information, reducing misunderstandings and enabling a more synchronized operation. Real-time visibility into the supply chain not only improves operational efficiency but also enhances trust among stakeholders, as it fosters a culture of transparency and accountability.

Collaboration Planning with Suppliers and Logistics Partners

The digital transformation of supply chain networks also facilitates collaborative planning with suppliers and logistics partners. This collaborative approach involves sharing forecasts, production schedules, and demand signals to align operations and optimize the supply chain as a whole. By working closely with suppliers and logistics partners, companies can ensure a more stable supply of materials, identify bottlenecks before they become critical, and develop contingency plans to address potential disruptions. This proactive planning is essential for minimizing risks and ensuring the timely completion of large industrial projects.

Resilience and Risk Management

The ability to manage risks and maintain resilience has become crucial for the success of large industrial projects. The unpredictable nature of today’s business environment, characterized by volatile markets, geopolitical tensions, and environmental uncertainties, necessitates robust resilience and risk management strategies.

Adoption of Predictive Risk Analytics

The use of predictive risk analytics represents a significant leap forward in proactively managing potential supply chain disruptions. Leveraging big data, AI, and machine learning, predictive analytics enables companies to anticipate risks before they materialize.

This foresight allows companies to move from a reactive to a proactive stance, implementing preventive measures and mitigating strategies to avoid disruptions or minimize their effects. The adoption of predictive risk analytics not only enhances supply chain resilience but also supports more informed decision-making, helping companies navigate through uncertainties with greater confidence.

Strategies for Building Resilient Supply Chains

As we learned from the COVID-19 pandemic, building a resilient supply chain is essential for ensuring the continuity of operations and safeguarding against potential losses. The foundation of resilience lies in the ability to quickly adapt to and recover from disruptions.

Contingency planning is a critical component of a resilient supply chain. This involves developing comprehensive plans that outline specific actions to be taken in response to various disruptive scenarios, such as natural disasters, supplier failures, or transport interruptions. Effective contingency planning requires a thorough understanding of the supply chain’s vulnerabilities, critical dependencies, and potential impact of disruptions on operations.

This will include identifying alternative suppliers, diversifying logistics routes, maintaining strategic stockpiles of critical materials, and establishing flexible manufacturing capabilities. Additionally, leveraging technology to enhance visibility and communication across the supply chain can significantly improve the speed and coordination of response efforts.

Embracing Material Logistics Trends for Sustainable and Efficient Supply Chains in 2024

In 2024, material logistics is at the forefront of transforming large industrial projects through technological innovation, sustainability, and enhanced collaboration.

With the global logistics market on a rapid growth trajectory, integrating IoT, AI, and automation is pivotal for optimizing supply chain operations, demonstrating a shift towards smarter, more efficient management practices.

Sustainability takes center stage with eco-friendly packaging and greener transportation methods, significantly reducing the environmental impact of logistics activities. The adoption of electric, hybrid, and rail transport, alongside predictive analytics and strategic contingency planning, underscores a commitment to resilience and risk management in an unpredictable business environment.

These trends not only advance operational capabilities but also position material logistics as a critical driver for sustainable, efficient, and resilient global supply chains, marking a new era in industrial project management.

Did you enjoy this post? You might also be interested in our blog posts on

- Material efficiency in capital projects

- Review from material suppliers on modern materials management tools in capital projects

- Implementing new software in capital projects- how to get supplier buy-in?

References

- https://www.cleo.com/blog/logistics-management-trends

- https://en.innovamaquinaria.com/news/challenges-and-trends-in-the-logistics-sector-for-2024-full-digitalization-ai-and-sustainability/

- https://dhl-freight-connections.com/en/trends/logistics-trends-2023-2024/*

- https://3pllinks.com/materials-logistics-tips-construction-industry/#:~:text=Material%20logistics%20is%20defined%20as,and%20delivering%20troops%20and%20equipment.

- https://www.precedenceresearch.com/logistics-market

- https://www.statista.com/markets/419/topic/491/logistics/#overview

- https://www2.deloitte.com/us/en/pages/operations/articles/smart-sensors-and-supply-chain.html

- https://www.freightcenter.com/5g-transforms-the-freight-industry/#:~:text=5G%20technology%20helps%20improve%20supply,%2C%20providing%20real%2Dtime%20updates.

- https://www.forbes.com/sites/elijahclark/2024/01/28/revolutionizing-marketing-the-convergence-of-data-science-and-ai/?sh=7448425c1938

- https://www.leewayhertz.com/ai-in-logistics-and-supply-chain/#:~:text=With%20AI%2Dpowered%20optimization%2C%20logistics,increase%20speed%2C%20and%20improve%20efficiency.

- https://www.industrialpackaging.com/blog/6-benefits-of-sustainable-packaging

- https://sinay.ai/en/how-much-does-the-shipping-industry-contribute-to-global-co2-emissions/#:~:text=The%20maritime%20transportation%20industry%20contributes,the%20world’s%20greenhouse%20gas%20emissions.

- https://utilitiesone.com/sustainable-sea-transportation-reducing-emissions-and-energy-use

- https://www.aar.org/wp-content/uploads/2023/06/AAR-Climate-Change-Fact-Sheet.pdf

- https://maritime-executive.com/editorials/sailing-cargo-ships-are-making-a-genuine-comeback

- https://www.celona.io/network-architecture/warehouse-robotics

- https://www.aboutamazon.com/news/operations/how-amazon-deploys-robots-in-its-operations-facilities

- https://brownwestlogistics.com/blog/warehouse-contingency-plans-during-the-coronavirus-pandemic/