Engineering and Procurement

Procurement management software for projects gives you all information on one shared platform, transparent PO transmission and streamlined processes

Reliable procurement management software for projects and all material types

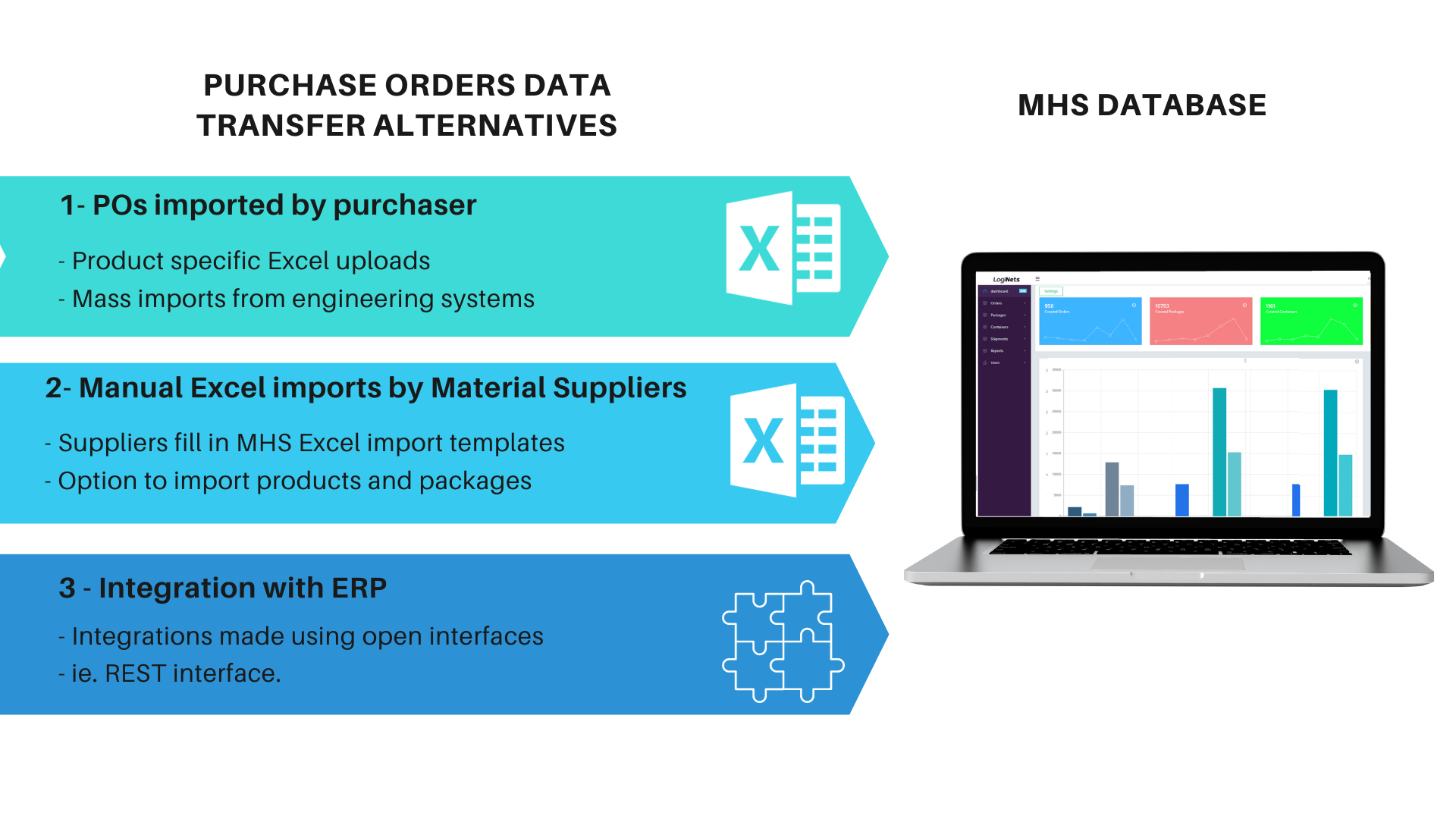

A reliable procurement management software for industrial projects, MHS offers a modern tool for publishing, handling and managing orders within the project’s network. Ensure transparent and smooth interaction between engineering, purchaser, logistics, material supplier and site personnel. The software supports all material types, for example piping, bulks, structures, tagged equipment, assemblies and spares. There are three primary ways to import call-off information to MHS.

Efficient tracking begins at transparent purchase order handling

- Supply chain event transparency. Information of all procured materials on one platform; get rid of Excel files and phone calls between individual people within an organization.

- Materials data-base for the entire project eco-system. Different project parties can publish orders into MHS. For example, if an EPC/M contractor orders a boiler plant from a specific sub-contractor, the sub-contractor can publish their material orders for the construction of the boiler plant via MHS.

- Streamlined processes. Suppliers have clear processes for material deliveries for your project. This ensures timely delivery of procured materials.

- Connect all project parties on one platform with extensive automation possibilities. Process planning and consulting companies’ softwares can be integrated with MHS to receive updates on the product status. For example, when a material supplier packs or confirms delivery of products.

- Materials data-base for the entire project eco-system. Different project parties can publish orders into MHS. For example, an EPC/M contractor may order a boiler plant from a specific sub-contractor, and the sub-contractor can publish their material orders for the construction of the boiler plant via MHS.

- Data integrity. Components and quantities of materials are subject to changes. Use the data in MHS to cross-check procurements in original call-offs, between SAP and ERP. Ensure that suppliers are delivering materials based on latest purchase order information.

- Efficient call-off handling between multiple contracts. Different project parties can publish orders into MHS. For example, the main contractor may order a boiler plant from a specific sub-contractor. The sub-contractor can then publish their material orders for the construction of the boiler plant via MHS. Suppliers will be able to view contracts that belong to them, ensuring that sub-contracted materials are delivered in a timely manner.

- Streamlined processes. Avoid late-fees and missed deliveries by following clear and streamlined material delivery processes. Suppliers get automatic notifications via email once an order has been published. Suppliers are guided to complete necessary steps by following the open task list when signing into the software. The procurement management software for projects will ease material handling throughout the process.

- Reliable payment release to ERP and SAP. Payment can be released, for example, after all order lines are received and inspected at the construction site.

- Pay bills based on delivered materials. Materials account for a huge portion of a capital project’s budget. Pay the suppliers’ bills based on the materials that were delivered and passed quality control.

- Supply chain event transparency. Information of all procured materials on one platform – get rid of Excel files and phone calls between individual people within an organization.

- Materials data-base for the entire project eco-system. Orders can be published into MHS by different project parties. For example, the main contractor may order a boiler plant from a specific sub-contractor, and the sub-contractor can publish their material orders for the construction of the boiler plant via MHS.

- Streamlined processes. Suppliers have clear processes for material delivires for your project – this ensures timely delivery of procured materials.

- Connect all project parties on one platform with extensive automation possibilities. Process planning and consulting companies’ softwares can be integrated with MHS to receive updates on the product status. For example, when a material supplier packs or confirms delivery of products.

- Materials data-base for the entire project eco-system. Orders can be published into MHS by different project parties. For example, the main contractor may order a boiler plant from a specific sub-contractor. The sub-contractor can then publish their material orders for the construction of the boiler plant via MHS.

- Data integrity. Components and quantities of materials are subject to changes. Use the data in MHS to cross-check procurements in original call-offs, between SAP and ERP. Ensure that suppliers are delivering materials based on latest purchase order information.

- Efficient call-off handling between multiple contracts. Orders can be published into MHS by different project parties. For example, the main contractor may order a boiler plant from a specific sub-contractor. The sub-contractor can then publish their material orders for the construction of the boiler plant via MHS. Suppliers will be able to view contracts that belong to them, ensuring that sub-contracted materials are delivered in a timely manner.

- Streamlined processes. Avoid late-fees and missed deliveries by following clear and streamlined material delivery processes. Suppliers get automatic notifications via email once an order has been published. Suppliers are guided to complete necessary steps by following the open task list when singing into the software.

- Reliable payment release to ERP and SAP. Payments can be released, for example, after all order lines are received and inspected at the construction site.

- Pay bills based on delivered materials. Materials account for a huge portion of a capital project’s budget. Pay the suppliers’ bills based on the materials that were delivered and passed quality control.

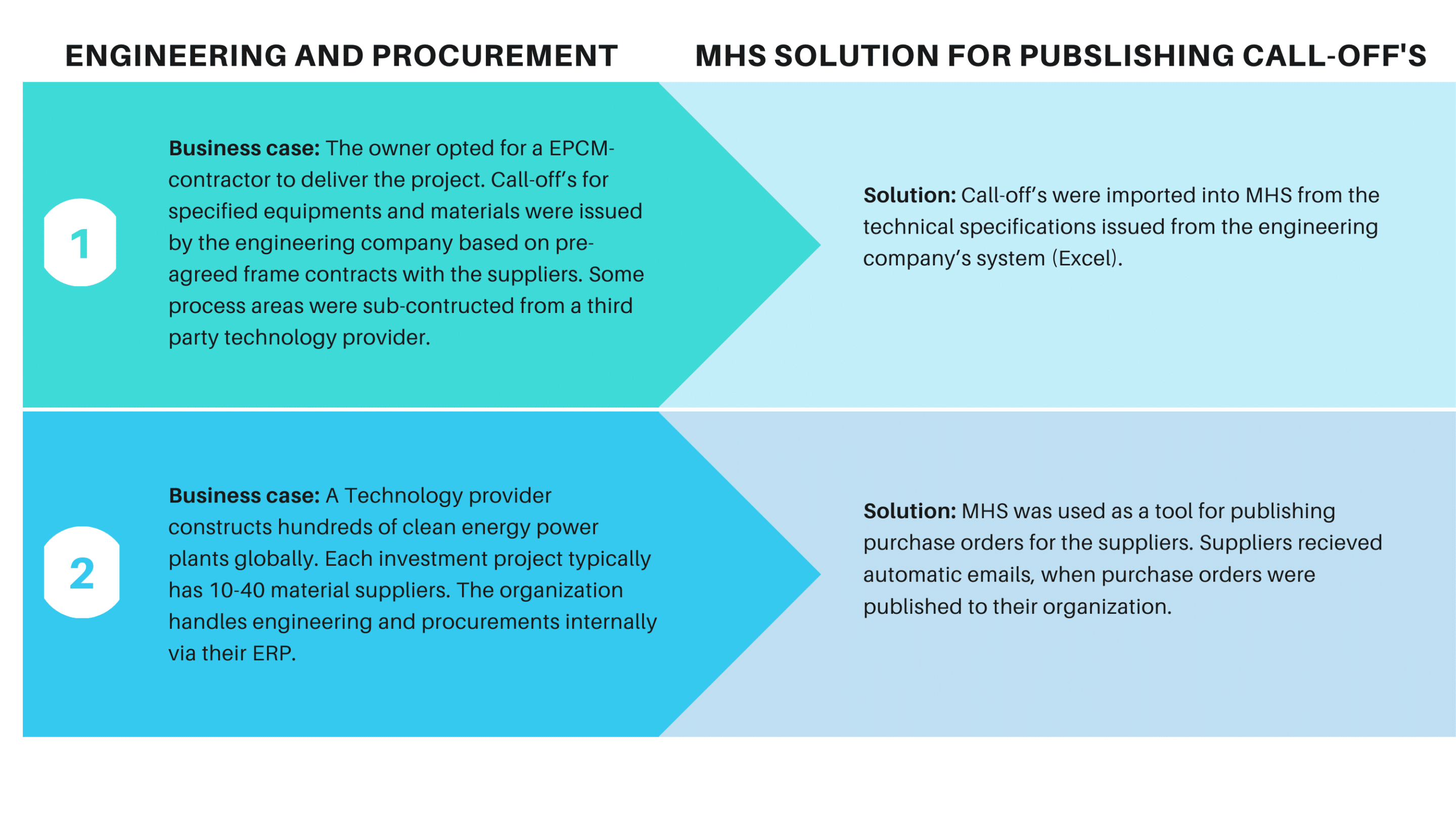

Typical business cases

There are two kinds of business cases that are often best solved with our Procurement Management Software for projects.

Procurement is the first concrete phase in projects of all sizes. It is important to do thoroughly in order to ensure fluent material flow throughout the project. MHS as a procurement management system will give all project parties visibility into the very basis of the operations. Read more about best practices in industrial project procurement in our blog!

Are you looking for a material tracking software?

Book a 30-minute online demo where we will give you a short overview of the Material Handling System and discuss how it can help you solve the challenges of your business.