Construction Site Warehouse Software

Manage inventory and storage locations on site, create pick-lists and monitor erection status with our easy-to-use construction site warehouse software

Streamlined Construction Site Warehouse Management

Along with other important features, MHS is also a Construction Site Warehouse Software. You can track all material-related information from procurement to site installations within one platform! This feature brings your project network significant benefits and eases to workload, as in large projects, there are usually various suppliers, and goods coming in from multiple locations all over the world. MHS will keep you updated on all of their statuses, schedules and locations. Real-time information on incoming deliveries and stock availability form a good foundation for assembly work planning. Once the work has been thoroughly planned, a detailed pick-list can be handed to the assembly employees with detailed identification of goods as well as their precise storage locations. If goods are stored in containers and wooden packages, this information can be identified in the pick-lists, with specific construction site storage codes and area numbers.

Once the goods are in assembly, the progress of construction can be reported with a mobile phone application. By simply clicking the image of the item that is being assembled on your mobile phone, you can update the status of the assembly to the common project data base. This way, the whole project network from start to finish have visibility to the status on site. The system also supports QR-codes.

Pick-list creation for assembly with MHS

Making processes as simple as possible is vital for a successful project. By eliminating unnecessary steps, the MHS construction site warehouse software will simplify process excecution and ensure your project is smoothly operated form start to finish.

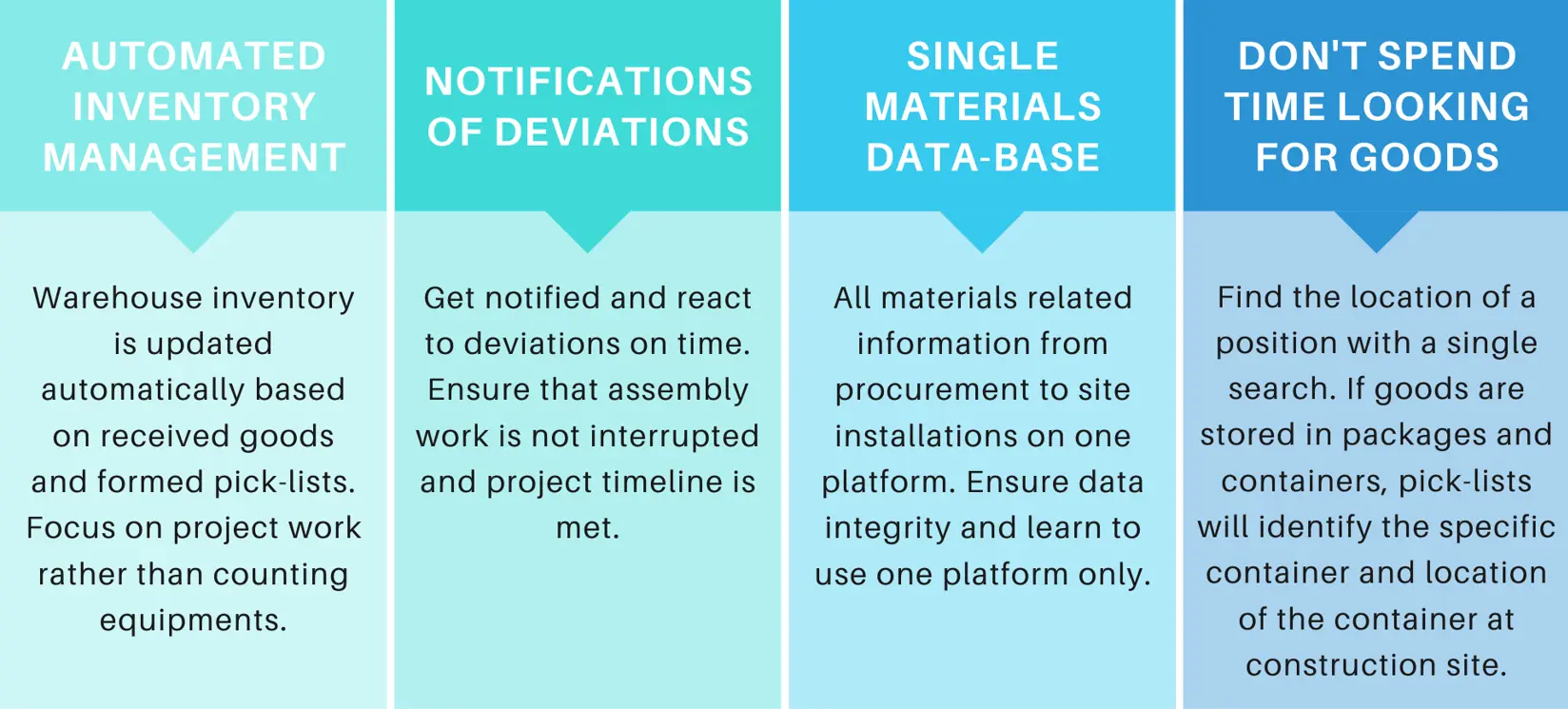

Benefits of MHS Construction Site Warehouse Software

The MHS construction site warehouse software has been developed over the years in order to be as smart, intuitive and easy to use as possible. Here, you can see the key benefits when it comes to warehouse operations at the construction site.

Storing materials at a construction site is an integral part of any large-scale industrial project. The materials, from large components to very small parts, spend varying times waiting on storage shelves. MHS is your solution to finding all parts fast and reliably. Read more about on-site material management in our blog!

Are you looking for a material tracking system?

Book a 30-minute online demo where we will give you a short overview of the Material Handling System and discuss how it can help you solve the challenges of your business.